Machines

Individual Design

Leveler DLAB

Leveler DLAB is a rectangular rake that aligns several units of product along its line. It is driven by the pneumatic system depending on the position of the products, which is tracked by means of sensors.

This solution is often used with the DLAS pusher, which is also developed by ME Food Solutions. This combination is a complete tunnel kiln unloading system and allows optimum filling of the conveyor surface at the exit of the kiln.

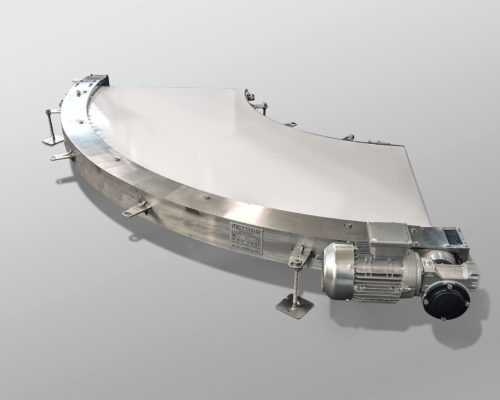

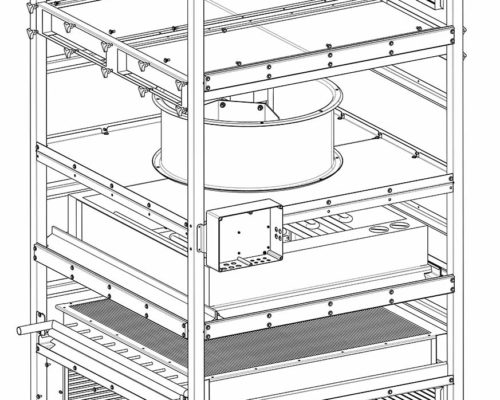

Combiner DLACO

Combiner DLACO combines several product series into one row. It can act as a separator and form multiple product series from one through working in the opposite direction.

The conveyor belt with the freely rotating rollers is provided with plates made of techno-polymer which diverge or converge (depending on the required task).These plates form the required number of product series at the output.

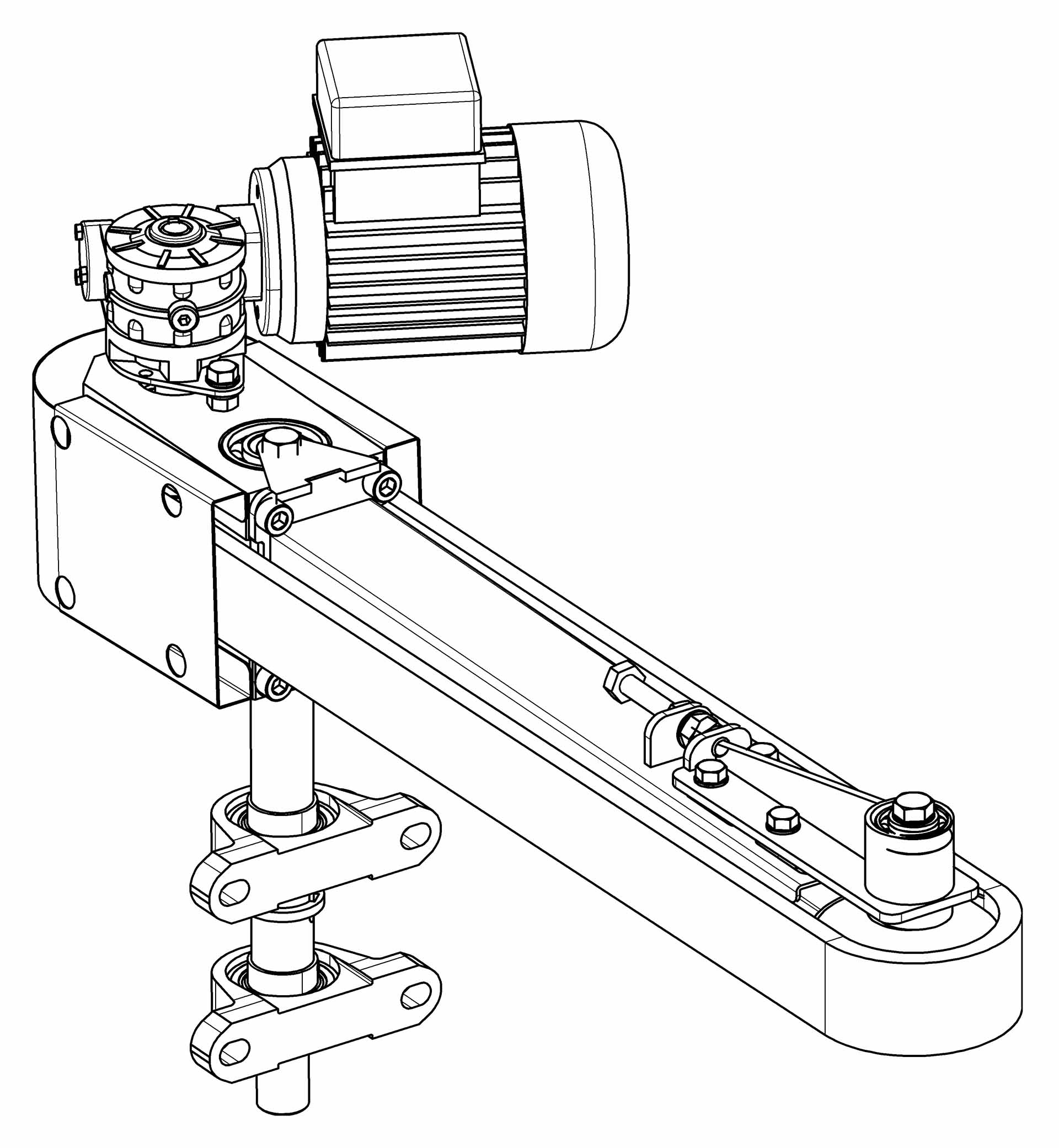

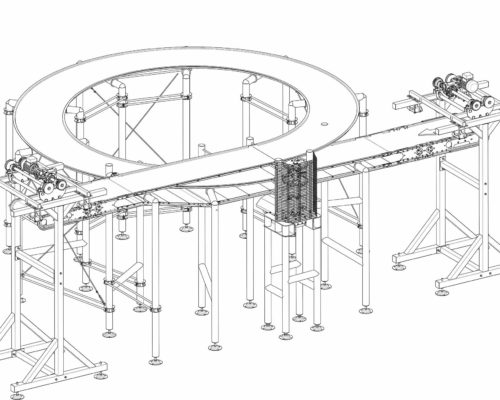

Deviator DLADV

It is one of the simplest but very effective devices produced by ME Food Solutions. It is installed on the side of the conveyor and is complete with an independent motor-reduction gear. It actually performs the function of the «movable arm» controlled through the HMI interface. With this equipment, the product can be grouped on one side of the conveyor or diverted to another conveyor line.

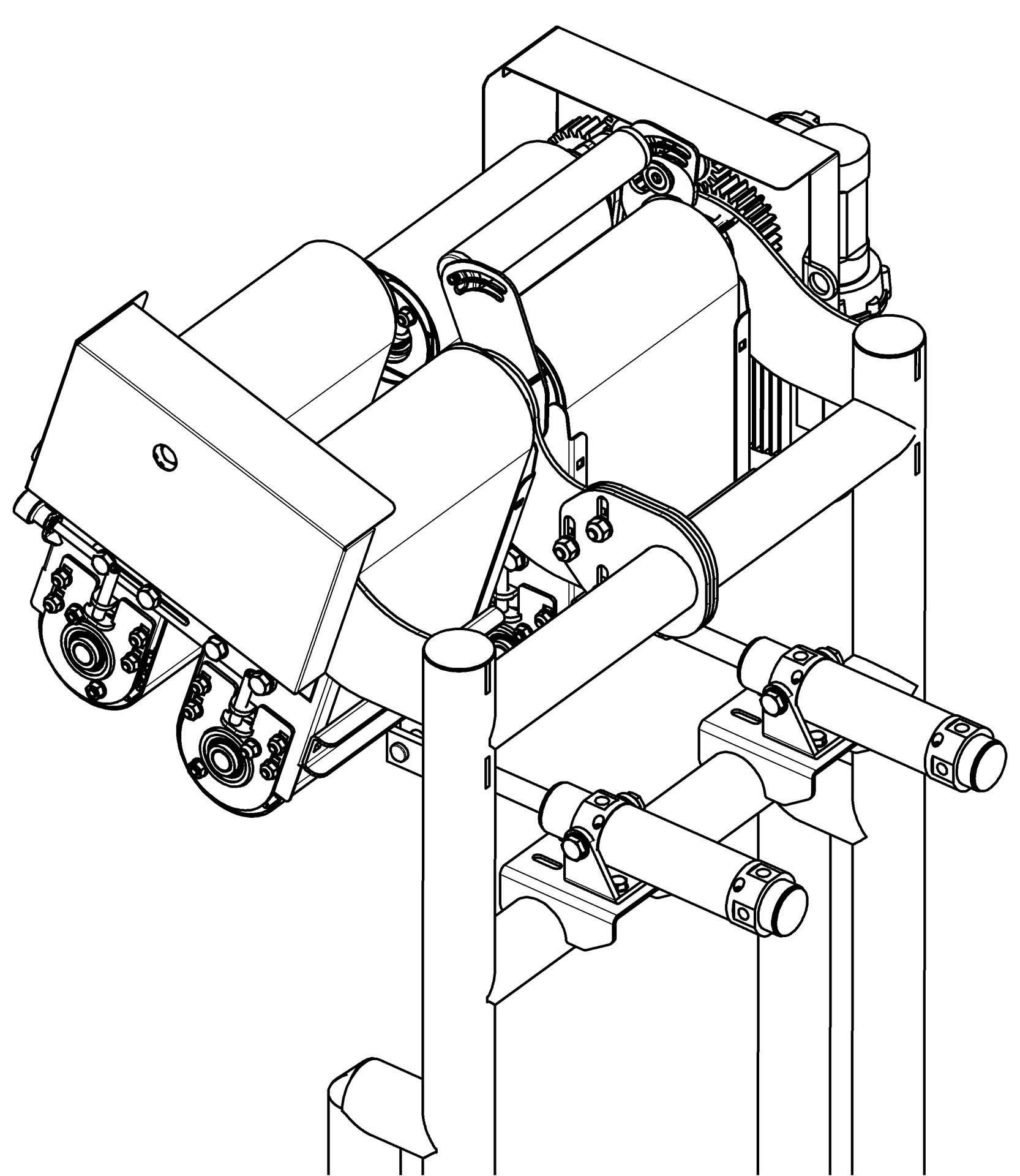

Molder DLAFM

A molder is a device for processing test blanks, which shapes them and can also redirect them to other conveyor lines for further processing. It consists of two parallel synchronized conveyor belts which operate from one motor-reduction gear. The distance between the belts is adjusted according to the desired product thickness at the outlet.

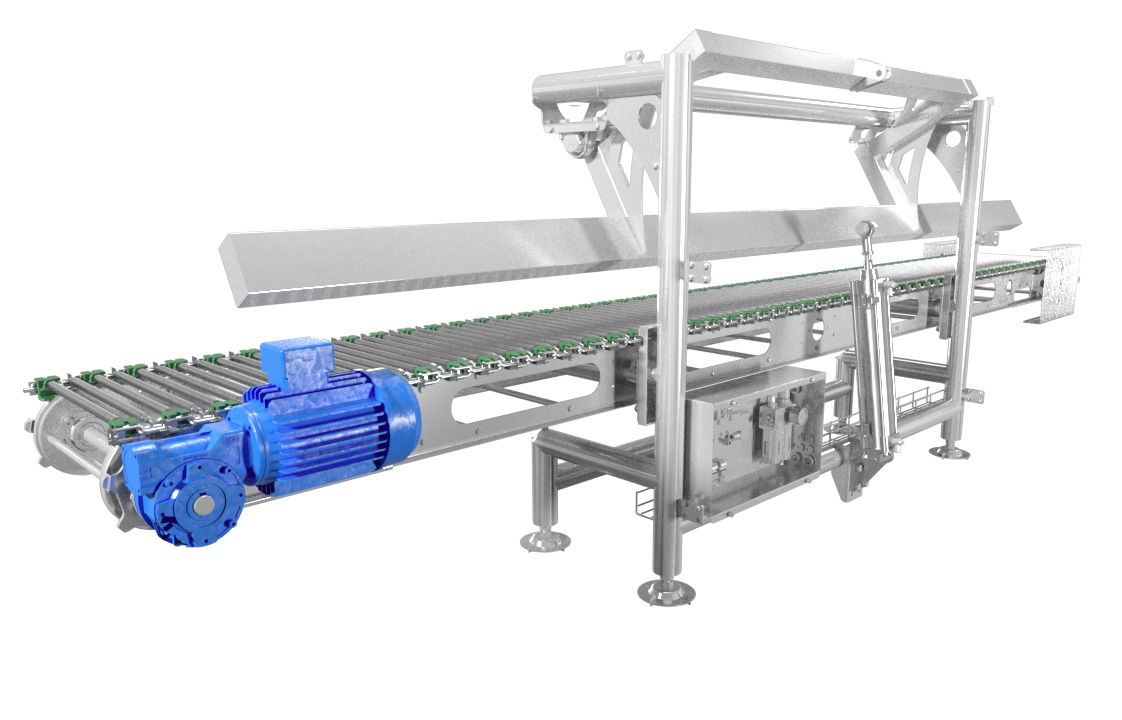

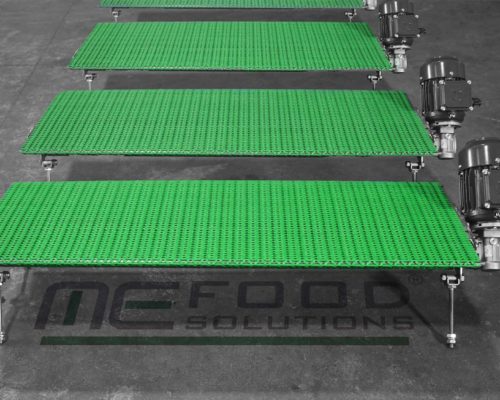

Pusher DLAS

The DLAS pusher is mounted on the conveyor and serves to redirect products to the following conveyor which is located under 90°. With the aid of sensors, a set number of units of a product passes along the belt and activates a pneumatic piston which redirects the products to the next transporter. The operation of this equipment is controlled by an HMI interface.